Hi-gee Bed (high efficiency distillation equipment)

Intro

Hi-gee bed (also known as Hi-gee rectifier, Hi-gee rectification column) is a new type of high-efficiency rectification equipment, which was invented by Zhejiang University of Technology and Hangzhou Keli Chemical Equipment Co., Ltd.Detail

Product introduction:Hi-gee bed (also known as Hi-gee rectifier, Hi-gee rectification column) is a new type of high-efficiency rectification equipment, which was invented by Zhejiang University of Technology and Hangzhou Keli Chemical Equipment Co., Ltd. The company jointly developed and pioneered the application of Hi-gee technology to the continuous distillation process in industrial production. The Hi-gee bed consists of one or more high-speed rotating rotors, and the gas and liquid flow through the rotors in a reverse baffled manner for contact mass transfer. A major breakthrough in traditional plate towers and packed towers was identified by a national expert group, and the products reached the international advanced level (invention patent numbers: ZL011343214, ZL200510049145.1, US patent US 7,344,126 B2). In 2007, he was awarded the National Science and Technology Innovation Fund, the first prize of China Petroleum and Chemical Industry Association Science and Technology Progress Award in 2008, and the second prize of Science and Technology Invention Award of the Ministry of Education in 2010.

Advantages of ultra-gravity distillation technology:

⑴Good performance, high efficiency and low energy consumption;

⑵Low height, small size, safe and reliable;

(3) Short treatment time, small liquid holding capacity, and strong anti-blocking ability;

⑷Simple operation and easy maintenance;

⑸ Low investment and low management cost.

Scope of application: Widely used in the recovery and recovery of organic solvents such as ethanol, methanol, acetone, ethyl acetate, acetonitrile, tetrahydrofuran, dichloromethane, DMF, DMSO, toluene, isopropanol, tert-butanol, etc. Product separation and purification has been applied in more than 1,600 sets of industrialization in industries such as APIs, pharmaceutical intermediates, fine chemicals, biodiesel, environmental protection, and wine making. For more details, see the Hi-gee column

Single system conventional material handling capacity

|

Raw material parameters |

50% methanol and water |

50% ethanol and water |

50% acetone and water |

|

Product purity |

≥99.5% |

≥95° |

≥98% |

|

Content in waste liquid |

≤0.5% |

≤0.5% |

≤0.5% |

|

Minimum model throughput |

400 kg/h |

200 kg/h |

450 kg/h |

|

Maximum model capacity |

1300 kg/h |

800 kg/h |

1500 kg/h |

|

Design detailed plans according to material information, tailor-made, save energy and reduce consumption |

|||

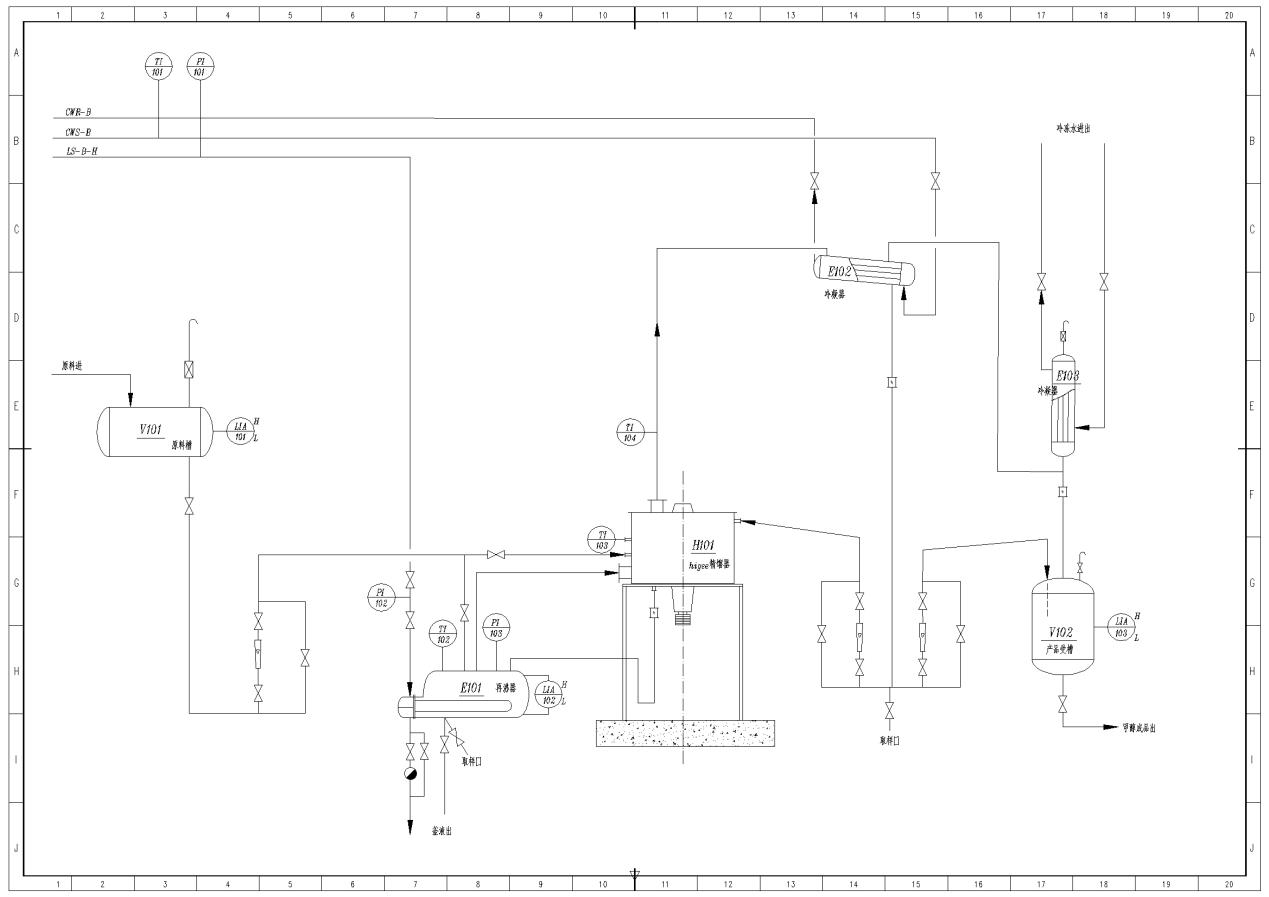

Schematic diagram of the process

List of conventional configuration equipment for a single rectification system

|

Serial number |

Device name |

Quantity |

|

Serial number |

Device name |

Quantity |

|

1 |

Hi-gee bed |

1 |

6 |

Flowmeter |

3 pcs |

|

|

2 |

Heating kettle (reboiler) |

1 |

7 |

Pressure gauge |

2 |

|

|

3 |

Main condenser |

1 |

8 |

Electronic control system |

1 set |

|

|

4 |

Tail condenser |

1 |

9 |

Automatic control system (optional) |

1 set |

|

|

5 |

Thermometer |

3 |

10 |

storage tank |

Several |

|

|

The buyer can choose to purchase a single machine, or some/all of the above equipment, or a complete set of skid-mounted devices. |

||||||

Ultra-gravity bed sheet machine equipment parameter table

|

First Name Name |

Parameters Number |

||

|

Equipment Specifications |

Design according to needs |

||

|

Rotor diameter |

650-1100mm |

Rotor layers |

2-4 |

|

Design speed |

900-1100rpm |

Transmission mode |

Belt drive or direct motor connection |

|

Work pressure |

Atmospheric pressure or negative pressure |

Working temperature |

<200℃ |

|

Material |

The material in contact with the material can be selected from 304 stainless steel and 316L stainless steel Steel, Titanium |

||

|

Motor power |

5.5Kw-75Kw, protection class: IP54, explosion-proof class: dIIBT4 |

||

|

Appearance and weight of stand-alone equipment |

Minimum: length 1300mm× width 800 mm× height 2100mm, 1200kg Maximum: length 2000mm× width 1250mm× height 2550mm, 3800kg |

||

|

Industrialization time of the first equipment |

July 2004, still in normal use |

||

|

The number of industrialization by the end of 2021 |

More than 1600 units, nearly 500 users |

||

For more details, see the Hi-gee column